Flue oxygen analyzer has a variety of fault information prompting functions. Self-contained fault detection function can improve troubleshooting efficiency and self-protection ability. PID automatic temperature control circuit, fast and accurate heating, can eliminate the influence of external environment on temperature control. With its own fault detection function, it can improve the efficiency of troubleshooting and self-protection ability.

Flue oxygen analyzer main features:

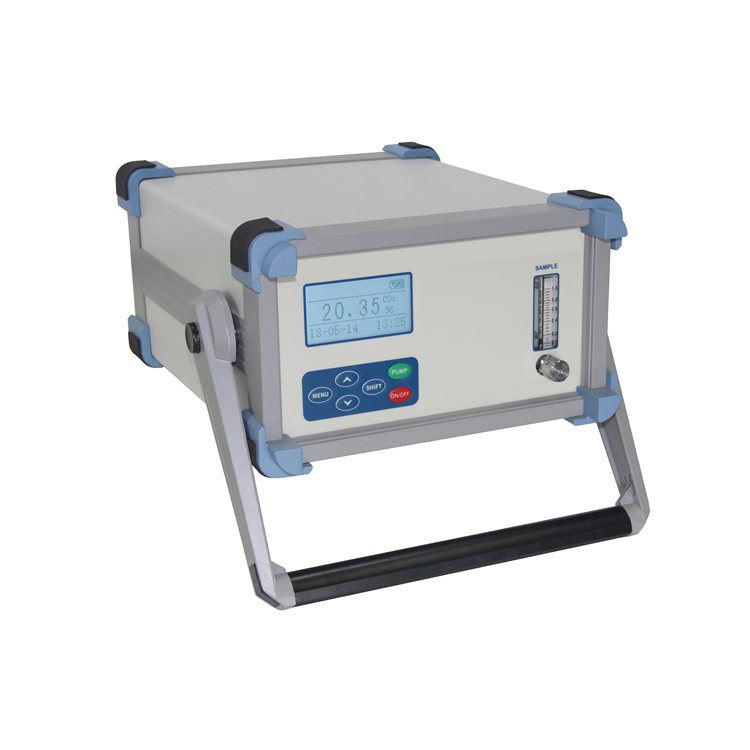

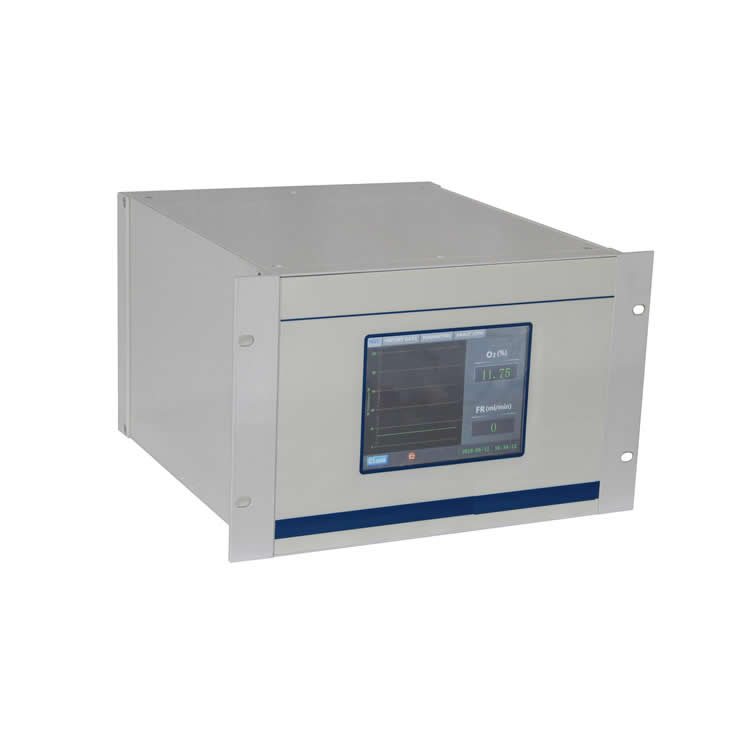

1.High-bright OLED active light display, intuitive display;

2.The new zirconia sensor has extremely small drift, fast response and high precision.

3. Add coating on the pipe wall of the sensor contacting the flue gas to reduce the corrosion of the sensor caused by the corrosive gas and extend the service life;

4.The contact part of the oxygen probe and the flue gas adopts a new high-temperature alloy steel, and the oxygen probe can be directly inserted into the furnace chamber below 650℃;

5.Two-point calibration can meet the measurement accuracy of the entire range;

6.The probe and meter are IP54 protection class (except he probe front end);

7.Users can freely set the 4-20mA (default) or 0-10V (optional) output corresponding to the upper and lower limit value, so that users can get higher precision analog output;

8.Standard RS232 (default) or RS485 (optional) communication interface for two-way communication with a computer or other digital communication device.

Flue oxygen analyzer technical parameters:

Measuring principle | zirconia |

Display mode | 128×64 dot matrix OLED |

Measuring range | 0.01% ~ 21.00% O2 |

Measurement accuracy | <±1.0%.FS |

Repeatability | <±0.5%.FS |

Stability | <±1%.FS (24 hours) |

Resolution | 0.01% |

Response time | T90 ≤ 5S |

Analog output | 4~20mA.DC (default) or 0~10V.DC (non-isolated output, 4 ~ 20mA load resistance ≤ 500 ohm, 0 ~ 10V load resistance > 10K ohm) 2-way programmable dry contact passive alarm output, contact maximum capacity 220VAC/2A |

Other interfaces | RS232 (default) or RS485 |

Calibration method | online calibration |

Power supply | AC220V±10% 50/60Hz, ≤100W |

Working temperature | Meter : -10 ~ +50℃ Probe:0 ~ 650℃ |

Background gas | burning fumes (except for strong corrosion and reducing gases) |

Hole size | Φ70mm~Φ90mm |

Connection method | Meter and probe connection cable (standard 3 meters) |

Probe length | Standard length is 1110mm (other lengths can be customized) |

Service life | >60 months (under normal use conditions) |

Installation method | Probe: plug-in type, meter: wall-mounted |

Disclaimer: The product introduction content (including product images, product descriptions, technical parameters, etc.) of this site is for reference only. As the update may not be timely, there will be some differences between the content and the actual situation. Please contact our sales staff to confirm. The information provided on this site does not constitute any offer or promise, and the company will improve and modify any information on the website from time to time without prior notice.